Welcome to our company !

Call Us08045801547

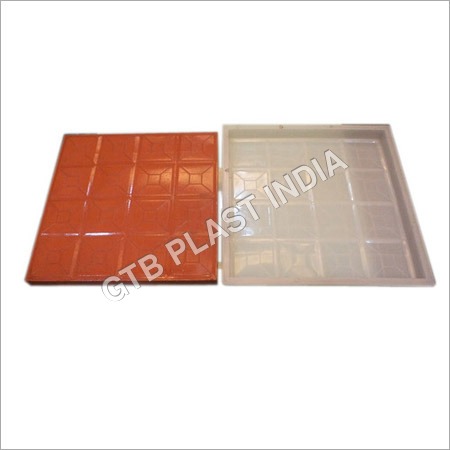

Square Designer Chequered Tiles Moulds

Product Details:

- Usage For Tile Making

- Material Plastic

- Size 300x300 mm

- Height 25 Millimeter (mm)

- Product Type Tiles Moulds

- Color White

- Click to View more

X

Square Designer Chequered Tiles Moulds Price And Quantity

- INR

- 500 Unit

Square Designer Chequered Tiles Moulds Product Specifications

- 300x300 mm

- 25 Millimeter (mm)

- Tiles Moulds

- White

- Plastic

- For Tile Making

Square Designer Chequered Tiles Moulds Trade Information

- Cash on Delivery (COD), Paypal, Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 15000-20000 Unit Unit Per Day

- 5 Days

- Carton Box

- Western Europe, South America, Middle East, Central America, Eastern Europe, Africa, Australia, Asia, North America

- All India

Product Description

Under stern supervision of our experienced professionals, offered Square Designer Chequered Tiles Moulds are precisely manufactured by making use of the best quality raw materials with the aid of advanced techniques. These moulds are widely preferred for making standard size tiles. Furthermore, these Square Designer Chequered Tiles Moulds can be customized according to the requirements for our customers.

Features:

- Designed for providing optimum finish

- Durability of these moulds allow multiple usage

- Robust and precision designed

- Free from external damages

Technical Specifications

| Material | PVC |

| Brand | GTB Plast |

| Shape | Square |

| Height | 40 to 150 mm |

| Texture | Plain and Sand |

Specifications:

- Size: 300 mm x 300 mm x 25 mm

Premium Quality and Durability

Manufactured from robust plastic material, these tile moulds are designed to withstand regular usage and offer consistent results. The size and shape ensure that each tile produced meets industry standards for strength and finish, making them suitable for high-traffic areas.

Aesthetic Versatility

With their chequered pattern, these moulds deliver visually striking tiles that enhance the look of pavements, walkways, and various interior or exterior settings. Their classic white color lets manufacturers experiment with various pigments for customized tile designs.

FAQs of Square Designer Chequered Tiles Moulds:

Q: How are Square Designer Chequered Tiles Moulds used in tile making?

A: These moulds are used by pouring concrete or tile mix into them, allowing the material to set and take the chequered shape. Once cured, the mould is removed, leaving behind a perfectly shaped tile ready for use.Q: What is the main benefit of using 25 mm height chequered tile moulds?

A: The 25 mm height provides enhanced durability and strength to each tile, making them ideal for both heavy-duty outdoor use and decorative indoor flooring, ensuring longevity and resilience.Q: When should these plastic tile moulds be used during the tile manufacturing process?

A: These moulds should be used after preparing the concrete or tile base mix and just before the curing stage. Once the mix is poured, it sets into the moulds shape, producing uniform tiles every time.Q: Where can these chequered tile moulds be supplied from?

A: These moulds are manufactured, supplied, and exported by a reputable company in India, ensuring reliable shipping and support for customers both domestically and internationally.Q: What process should be followed for optimal results when using these moulds?

A: Ensure the moulds are clean and lightly greased before pouring the mix to prevent sticking. Fill evenly, vibrate gently to remove air bubbles, and let the material settle fully before demoulding.Q: What advantage does the 300x300 mm size offer for tile producers?

A: A 300x300 mm tile size strikes a balance between manageability and coverage, making it versatile for a wide range of applications, from walkways and driveways to patios and commercial spaces.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email