Welcome to our company !

Call Us08045801547

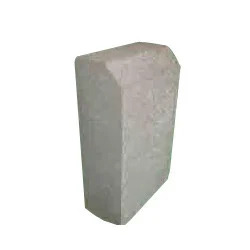

Plain Kerb Stone Moulds

Product Details:

- Usage For Landscaping

- Material Plastic

- Size 600 X 300 mm

- Height 40 to 150 Millimeter (mm)

- Product Type Kerb Stone Moulds

- Color White

- Click to View more

X

Plain Kerb Stone Moulds Price And Quantity

- INR

- 500 Unit

Plain Kerb Stone Moulds Product Specifications

- For Landscaping

- Kerb Stone Moulds

- Plastic

- 600 X 300 mm

- 40 to 150 Millimeter (mm)

- White

Plain Kerb Stone Moulds Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque

- 15000-20000 Unit Per Day

- 5 Days

- Carton Box

- Western Europe, Australia, Middle East, Central America, Eastern Europe, Africa, South America, Asia, North America

- All India

Product Description

With support of our techno-savvy group, we are able to manufacture, export and supply Plain Kerb Stone Moulds. These moulds are manufactured in compliance with set international quality standards using supreme quality raw materials under the observation of our professionals. Offered moulds are extensively used for making various attractive tiles for pathways and peripherals. Besides, these Plain Kerb Stone Moulds are available in different customized specifications according to the requirements of our customers.Features:

- Excellent finish and easy to clean

- Highly durable and accurate dimensions

- Light weight and robustness

- High strength and reusable

- 300 mm x 300 mm x 75/100 mm

- 300 mm x 450 mm x 100/150 mm

- 300 mm x 200 mm x 60/100 mm

- 300 mm x 350 mm x 100 mm

- 155 mm x 300 mm x 400 mm

- 200 mm x 250 mm x 60 mm

- 200 mm x 350 mm x 60 mm

- 300 mm x 600 mm x 75/100 mm and many more

Technical Specifications

|

Material |

KERB |

|

Texture |

Plain and sand |

|

Height |

6 inch |

|

Type |

Stone Moulds |

Versatile Landscaping Solution

Designed to simplify kerb installation, our moulds accommodate various landscaping requirements. They suit different projects by offering customizable heights and a sturdy plastic build that produces a smooth finish every time.

Export Quality Assurance

Manufactured in India to stringent quality standards, we supply these moulds not only domestically but also to international clients. Our export services ensure safe and timely delivery worldwide, making us a dependable partner for your bulk procurement needs.

FAQs of Plain Kerb Stone Moulds:

Q: How are the Plain Kerb Stone Moulds used in landscaping projects?

A: These moulds are used to cast kerb stones that define boundaries, pathways, or garden beds. Simply pour concrete or your preferred mix into the mould, allow it to set, and then remove the mould to reveal a perfectly shaped kerb stone, ready for installation.Q: What makes this mould suitable for kerb stone production?

A: The mould is designed with precise dimensions (600 x 300 mm) and constructed from durable white plastic, ensuring consistent shape, smooth surface quality, and easy demoulding. Adjustable height options cater to diverse project requirements.Q: When should I choose plastic moulds over other materials for kerb stones?

A: Plastic moulds are ideal when you need lightweight, reusable forms that are resistant to corrosion and easy to handle, particularly for repetitive kerb stone production in landscaping or construction projects.Q: Where are these kerb stone moulds manufactured and supplied from?

A: Our plastic kerb stone moulds are manufactured in India, where we operate as a reputable exporter, manufacturer, and supplier. We cater to domestic and international orders with prompt delivery services.Q: What is the process for using the Plain Kerb Stone Moulds?

A: To use, clean the mould, apply a release agent if desired, and pour in the concrete or chosen material. Tap gently to remove air bubbles, let it set for the required time, then demould and cure the kerb stone as per standard practice.Q: What benefits do these moulds offer for landscapers and builders?

A: They provide uniformity in kerb stones, save time in production, and are highly reusable due to their sturdy plastic construction. This results in reduced material waste and lower overall costs for large-scale projects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email