Welcome to our company !

Call Us08045801547

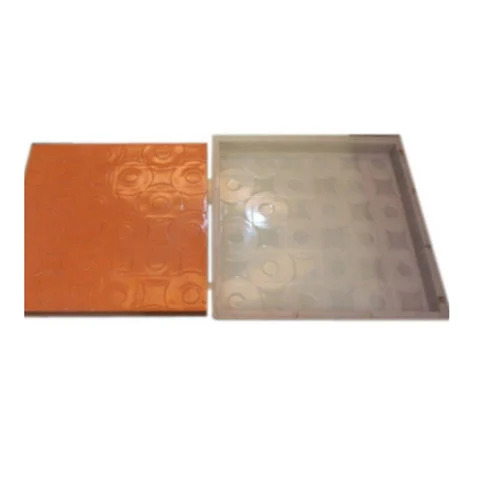

Kona Cut Chequered Tiles Moulds

Product Details:

- Usage For Construction

- Material Plastic

- Size 15x15 Inch

- Height 25 Millimeter (mm)

- Product Type Tiles Moulds

- Weight 300 Grams (g)

- Color White

- Click to View more

X

Kona Cut Chequered Tiles Moulds Price And Quantity

- INR

- 500 Unit

Kona Cut Chequered Tiles Moulds Product Specifications

- Tiles Moulds

- 300 Grams (g)

- Plastic

- For Construction

- 15x15 Inch

- White

- 25 Millimeter (mm)

Kona Cut Chequered Tiles Moulds Trade Information

- Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Paypal, Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 15000-20000 Unit Unit Per Day

- 5 Days

- Carton Box

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America, North America

- All India

Product Description

Holding great industry experience and in-depth knowledge of this domain, we are engaged in manufacturing, exporting and supplying premium quality Kona Cut Chequered Tiles Moulds. Offered moulds are manufactured using quality approved raw materials and sophisticated technology at par with international quality standards. These moulds are used for providing shapes to the tiles. Further, offered Kona Cut Chequered Tiles Moulds are highly cherished among clients for their optimum quality and flawless finish.Features:

- Dimensionally accurate

- Sturdy construction

- Excellent finish

- Low maintenance

Exceptional Build for Consistent Results

Kona Cut Chequered Tiles Moulds are engineered to provide consistent, precise tile shapes every time. The robust plastic ensures longevity, while the 25 mm height and 15x15 inch size are perfect for standard walkways or pavements. Whether youre a large-scale manufacturer or a local supplier, these moulds ensure that your chequered tiles maintain quality and uniformity throughout production.

Ideal for Construction Demands

Designed specifically for the construction industry, these moulds are light enough to handle easily (just 300 grams) but tough enough for repeated use. Their white color aids in visual inspection during the demoulding process, reducing errors and wastage. Suitable for export, they meet the high standards expected by builders, contractors, and suppliers throughout India and beyond.

FAQs of Kona Cut Chequered Tiles Moulds:

Q: How are Kona Cut Chequered Tiles Moulds used in the construction process?

A: These moulds are typically filled with concrete or other tile materials to shape chequered tiles for pavements or walkways. Once the material sets within the mould, it can be demoulded to create durable chequered tiles with a consistent 15x15 inch size and 25 mm thickness.Q: What are the key benefits of using these plastic tile moulds?

A: Kona Cut Chequered Tiles Moulds offer durability, reusability, and ease-of-cleaning. Their standardized size ensures uniform tiles for professional-looking projects, and the lightweight plastic makes handling and storage simple, reducing operating costs for manufacturers and suppliers alike.Q: When should these moulds be chosen over other materials for tile making?

A: These moulds are ideal when you require rapid, repeatable tile production, especially for mid- to high-volume needs. Their plastic construction offers longevity and cost savings compared to more fragile or rigid alternatives, making them suitable for both small workshops and large manufacturing units.Q: Where can I source Kona Cut Chequered Tiles Moulds in India?

A: These moulds are widely available from manufacturers, suppliers, and exporters throughout India. You can contact tile equipment suppliers or reach out directly to the manufacturer for bulk orders and export arrangements.Q: What is the process for cleaning and maintaining these moulds?

A: Cleaning is straightforward: simply wash with water and a mild detergent after each use to remove any residue. Proper maintenance ensures the moulds retain their shape and longevity, allowing for consistent production runs without deformation.Q: How does the size and weight of the mould benefit tile production?

A: The standard 15x15 inch size and 25 mm height facilitate uniform tile output, minimizing discrepancies. At only 300 grams, each mould is easy to handle during setup and demoulding, improving workflow efficiency and reducing manual fatigue during large batch productions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email